Merrill's Packaging

Celebrating over 60 years of excellence in quality packaging. We can create new designs or reverse engineer existing designs.

-

Your Trusted Thermoforming Partner

Celebrating over 60 years of excellence and quality in packaging. We can create new designs or reverse engineer old designs.

Celebrating over 60 years of excellence and quality in packaging. We can create new designs or reverse engineer old designs.

-

Scalable Capacity

We grow with you from concept to prototype, from the first parts to high volume production.

We grow with you from concept to prototype, from the first parts to high volume production.

-

Custom Tooling and Design

Trust us to transform your concept into reality. We produce top quality thermoformed trays on time and in budget.

Trust us to transform your concept into reality. We produce top quality thermoformed trays on time and in budget.

Critical Packaging

Precision Engineering for a Better World

Specializing in Critical Packaging for Medical Device, Pharmaceuticals, and Life Sciences

Industry Leading Custom Thermoformer with Exceptional Tooling, Design, and Process Capability

Expertise

Finger on the Pulse of Innovation

Custom Design

After your thorough Q&A session with us, our engineering team takes your objectives, specs, and ideas and then factors in contingencies like unit cost, long-term quality, and material handling requirements to come up with an initial package design. From that point forward, you will be consulted at every stage in an effort to boost quality, shorten turn around times, and minimize costs.

In-house Tooling

Any tiny flaw in the tooling means that mistake will be replicated over and over. We’ve developed a system of checks to ensure your tooling is flawless. With your approved CAD design, we can manipulate the geometry and export it to our Computer-Aided Manufacturing software (CAM) which allows us to write the mold program that can cut virtually any shape in a matter of hours.

Production

State-of-the-art machinery and automated processes ensure efficiency and accuracy in every production run. Throughout this final stage, our focus remains on optimizing production processes to scale effectively, meeting increased demand without compromising on quality. Rigorous quality checks and continuous communication guarantee that the end result aligns seamlessly with your vision.

Locations

Our Facilities Are Located In:

SF Bay Area, California

Alajuela, Costa Rica

Bridgewater, New Jersey

SF Bay Area, California

Global Headquarters

Alajuela, Costa Rica

Manufacturing Facilities

Bridgewater, New Jersey

Warehouse

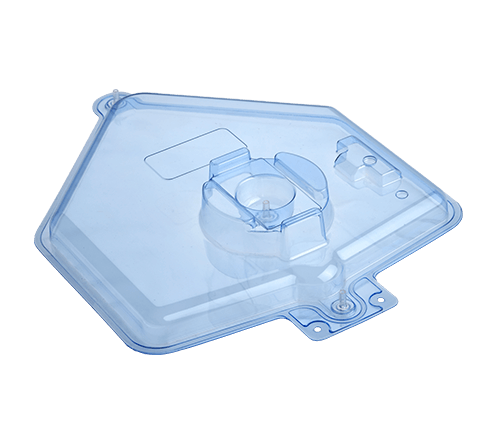

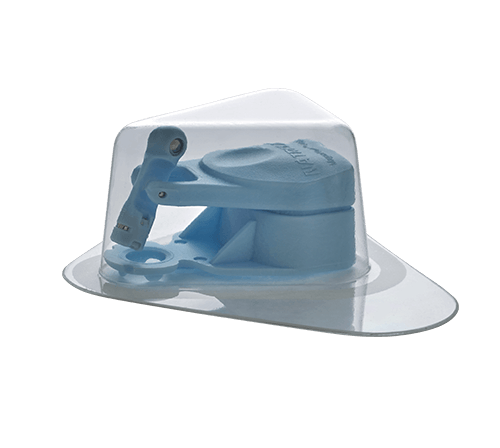

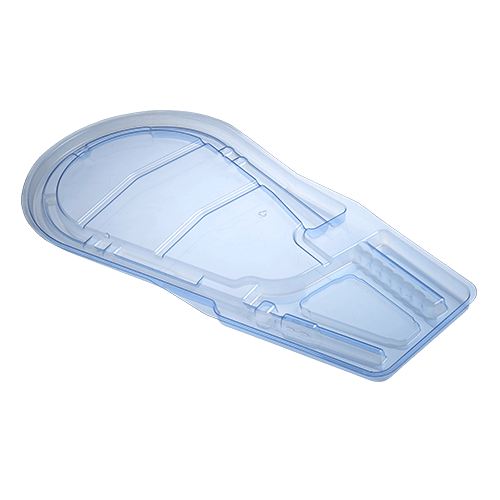

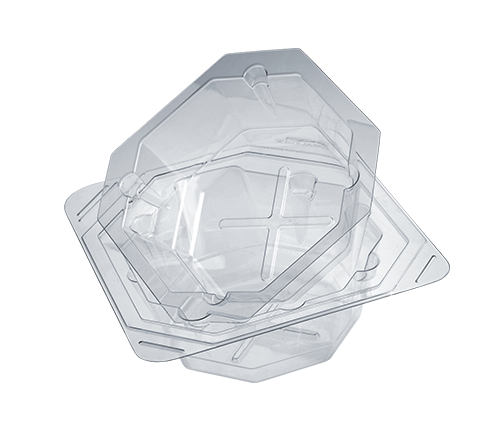

Sample Products

Packages We've Produced for Customers

Our Customers

Some of Our Loyal Customers